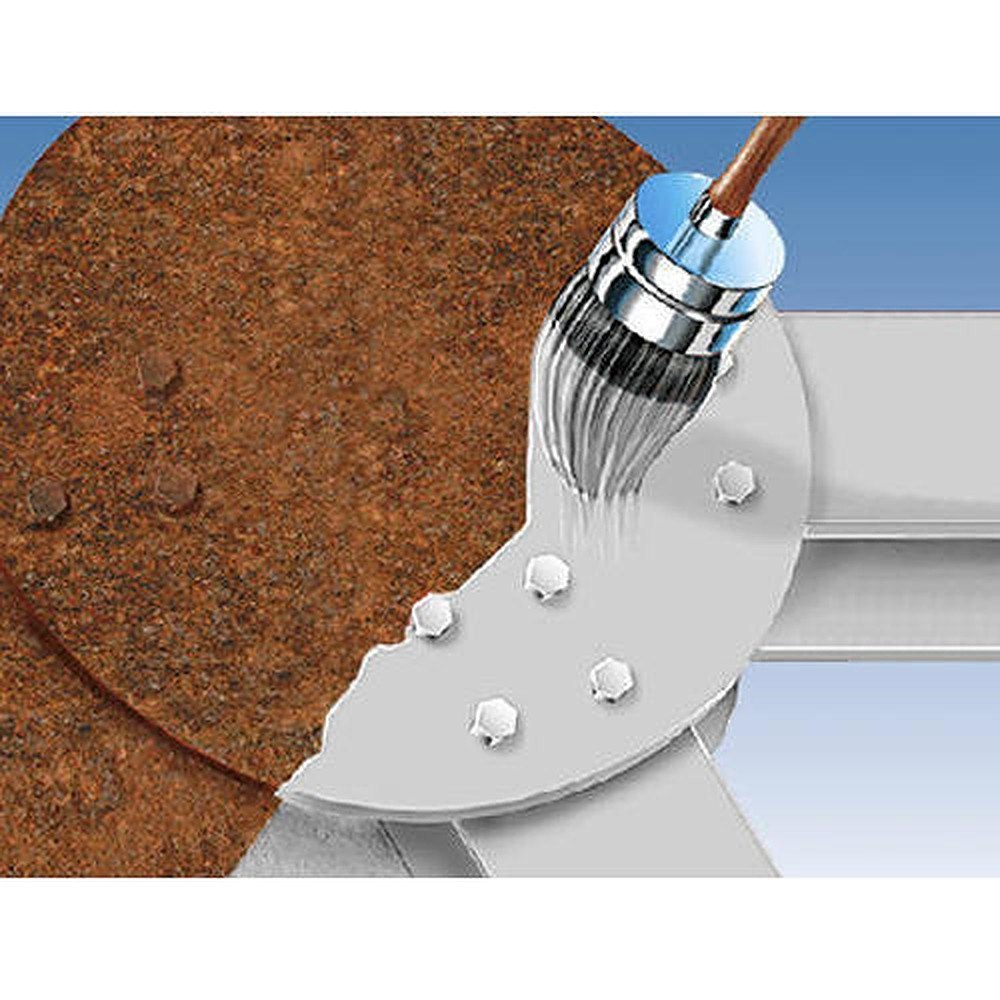

Anticorrosive pigments are special types of pigments used in coatings and paints to protect metal surfaces from corrosion. They work by forming a protective barrier between the metal and the environment, preventing the metal from reacting with moisture, oxygen, salts, and other corrosive agents. These pigments can be inorganic (like zinc phosphate, zinc chromate) or organic and often provide both physical and chemical protection to the metal substrate.